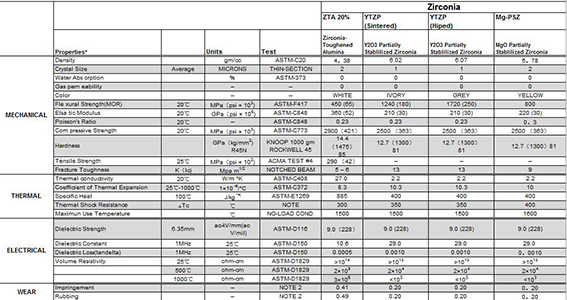

1. Zirconia (Download data sheet)

Zirconia is a range of “transformation toughened” ceramics that are inert to most chemicals, have exceptional strength, have high toughness and reliability which together result in outstanding resistance to wear and corrosion.Zirconia are frequently used to replace conventional metal alloys, hardened steels and tungsten carbides that suffer from wear and corrosion.

Zirconia are used in a wide variety of industries experiencing high maintenance costs, high downtime costs and poor product quality from lack of process control.

Industries as diverse as oil and gas, mining, food and battery production have enjoyed the benefits of long life, high production rates and low maintenance.

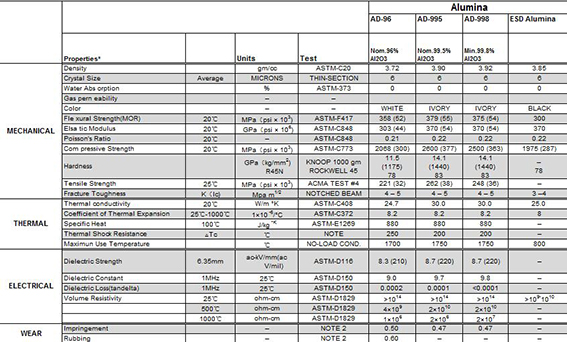

2. Alumina (Download data sheet)

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications.

Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques.

Alumina based ceramics are by far the largest range of advanced ceramics made by Highlives Technical Ceramic. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component.

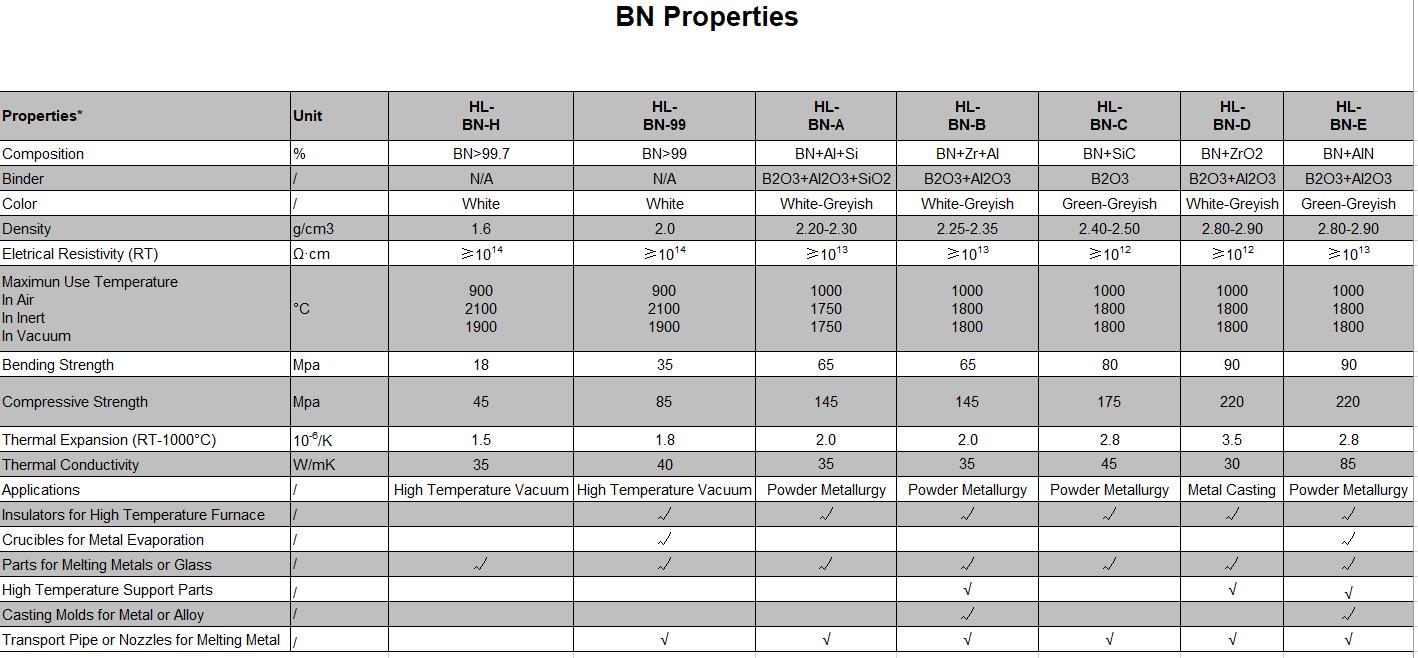

3. Boron Nitride(Download data sheet)

Boron nitride has a variety of excellent properties, widely used in high-voltage high-frequency electricity and plasma arc insulators, automatic welding high temperature frame coating, high-frequency induction furnace materials, semiconductor solid phase admixture, atomic reactor structure Materials, packaging materials for preventing neutron radiation, radar transmission windows, radar antenna media, and rocket engine components.

Due to its excellent lubricity, it is used as a release agent for high temperature lubricants and various models. Molded boron nitride can be used to make high temperature resistant crucibles and other articles. It can be used as a superhard material for geological exploration, oil drilling and high speed cutting tools. It can also be used as a metal working abrasive material, which has the characteristics of low processing surface temperature and few surface defects of components. Boron nitride can also be used as an additive for various materials. Boron nitride fiber made of boron nitride is a medium-modulus high-functional fiber. It is an inorganic synthetic engineering material widely used in the chemical industry, textile industry, aerospace technology and other cutting-edge industries.

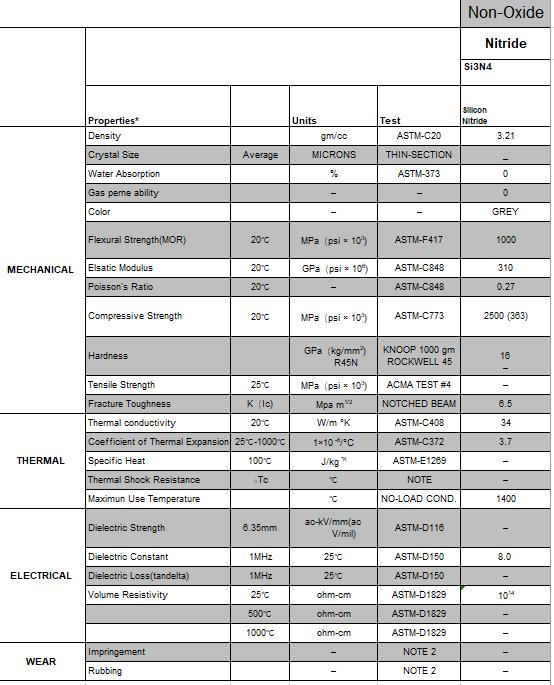

Silicon nitride is an important structural ceramic material. It is a superhard substance that is inherently lubricious and resistant to wear and is an atomic crystal; it is resistant to oxidation at high temperatures. Moreover, it can resist the thermal shock, and is heated to above 1000 ° C in the air, and is rapidly cooled and then heated rapidly without breaking.

Because of the excellent characteristics of silicon nitride ceramics, it is often used to manufacture mechanical components such as bearings, gas turbine blades, mechanical seal rings, and permanent molds. If a silicon nitride ceramic that is resistant to high temperatures and does not easily transfer heat is used to manufacture the heating surface of the engine component, not only the quality of the diesel engine can be improved, fuel is saved, but also thermal efficiency can be improved.

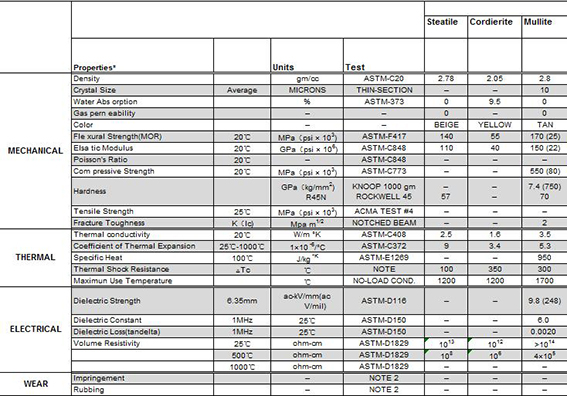

5. Other Material (Steatile/Cordierite/Mullite) (Download data sheet)

Contact: Diane Yang

Phone: +86-15858298013

Tel: +86-15858298013

Company: Highlives Technical Ceramic Co.,Ltd

Add: Room 501,5rd Floor,No.945 Jingchang Road,Xihu District,Hangzhou,China